RodlerBead Improves Building Envelopes

RodlerBead is a Combination Expansion Joint Strip with Strippable Screed Spacer, Masking Attachment, and Sealant Joint Backing Material. It is installed between exterior cladding elements to allow the adjacent material to expand and contract while maintaining a properly sealed flexible joint. Typical applications are between all fenestration (windows and doors), protruding decretive and structural members, specialty flashings and utility boxes.

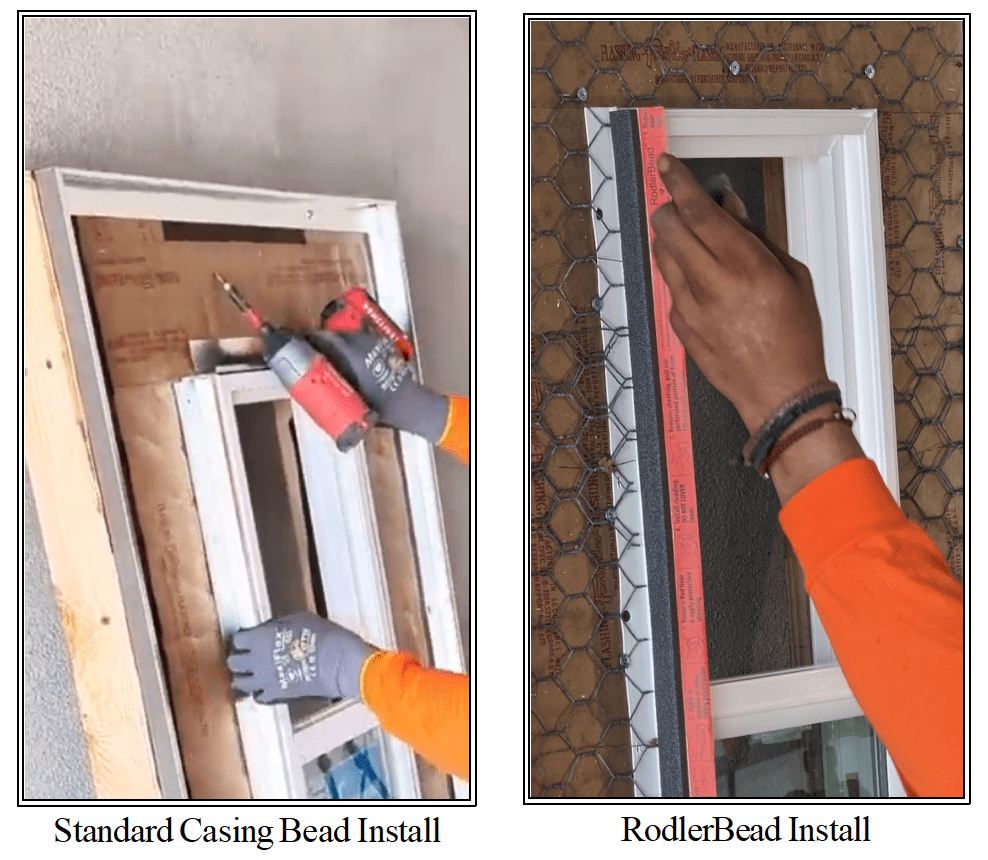

RodlerBead is adheres to the perimeter of the window, after the window is installed, and before the stucco is installed. Simply peel the first protective strip and stick it to the clean protruding item. RodlerBead can act as a screed during stucco installation, providing a uniform stucco edge against the window, at ⅞” deep.

After the stucco is installed, the exterior portion of the RodlerBead is removed, leaving a ⅜” wide and ⅜” deep sealant channel to be filled with an appropriate sealant. The sealant bead and remaining portion of RodlerBead form the required separation, with ideal dimensions, prescribed by most construction sealant manufacturers.

RodlerBead addresses often overlooked building codes and manufacturers requirements. Building Codes and Manufacturers require separation between windows and stucco to prevent water from getting within the stucco system through gaps between different materials caused by their differential rate of thermal expansion. Window and door manufacturers will always prefer that their products not be stressed laterally.

Some fenestration manufacturers ask for a flexible separation from siding. RodlerBead is the perfect way to create the gap and leave a clean well sized channel for sealant.

The California Building Code section 2510.3 requires that stucco be installed per ASTM C 926. ASTM C 926 requires that stucco be separated from windows. Section 7.1.4 states that Separation shall be provided where plaster abuts dissimilar materials or openings. See Building Code Requires Flexible Joints

Updated 9/13/24 MFC

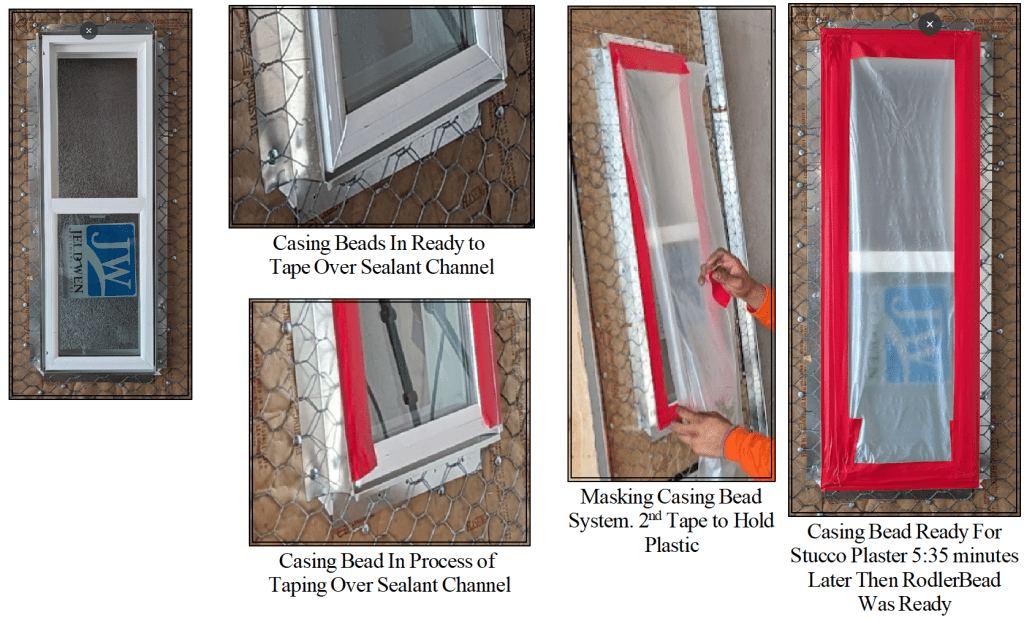

TYPICAL STANDARD Casing Bead System

1st Steps Both Systems

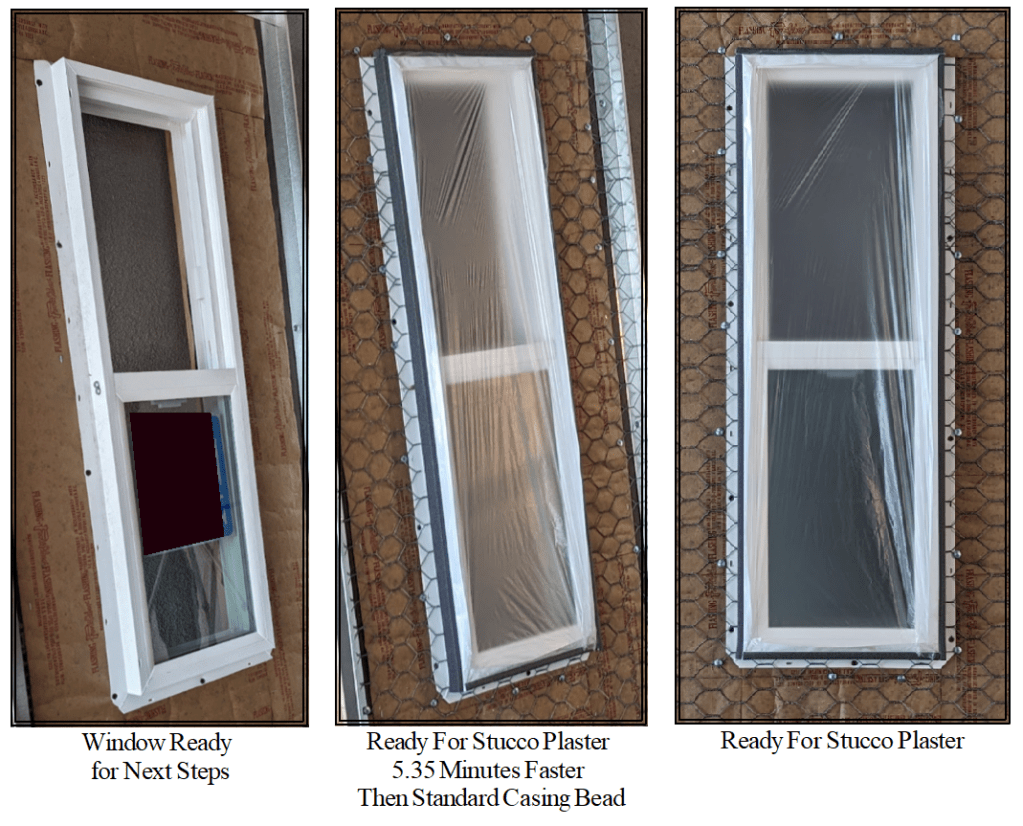

RodlerBead: Ready for stucco in minutes

Standard Casing: Bead Ready for stucco takes more time.

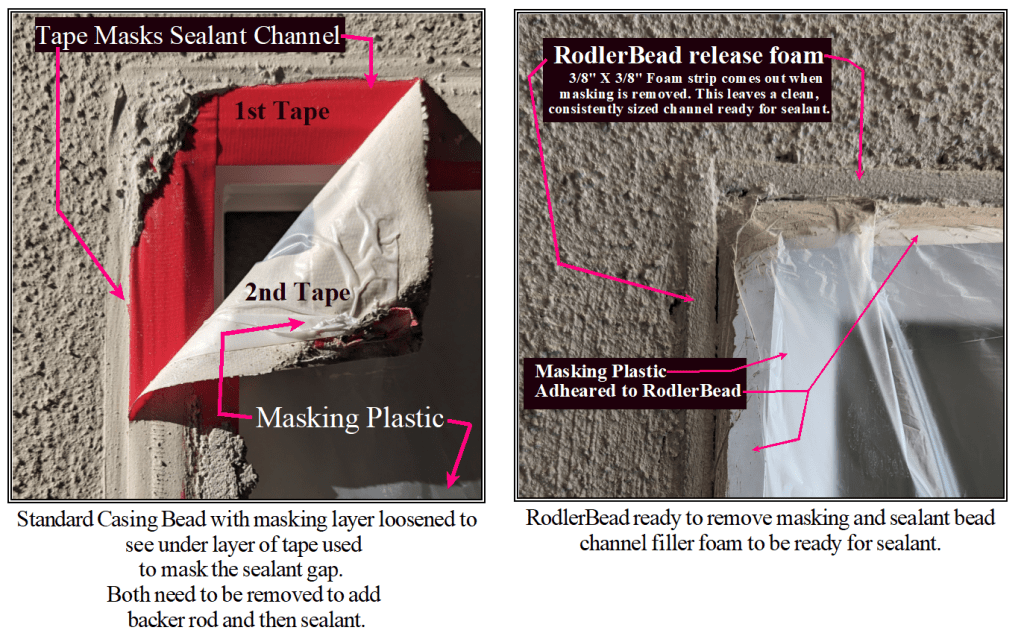

After Stucco Cure getting ready for sealing.

More time is saved when the stucco plaster is cured enough to remove the masking. With RodlerBead the masking and the outer 3/8″ of foam come off with a simple peel. With RodlerBead no tape is attached to the window/door face. RodlerBead is designed for easy removal. Note that with RodlerBead the sealant can adhere to both sides of the joint. With Standard Casing Bead a fissure will always exist between the metal and the stucco plaster.

With the Standard Casing Bead system there are two layers of tape to peel off the face of the building. Once the masking is removed in the Standard Casing Bead system Sealant Backer Rod is required to be installed at the proper depth in the open channel between the window/door and the Standard Casing Bead.

Removing the RodlerBead masking and plastic took 4 minutes less time than removing the two layers of tape, the plastic and installing the backer rod in the Standard Casing bead system.

In both systems the application of sealant takes the same amount of time.